제품

35KV oil-immersed transform with high efficiency

Product application:

35KV series transformers are mainly used in urban and rural power grids and other industries, industrial and mining enterprises, power transmission and distribution industries, as well as agricultural projects.

Core technology:

The transformer body adopts a high temperature resistant hybrid insulation system with optimal supporting components to achieve a design life of 30 years.

The oil-immersed transformer adopts the basic structure of the traditional transformer. The iron core is of iron core type, the high voltage winding adopts pancake coil, and the low voltage winding adopts wire winding or foil winding coil according to different capacities. The biggest difference from the traditional transformer is the use of high temperature resistant insulation paper.

The insulation structure of 35kV and below oil-immersed power transformers is a hybrid insulation system. The conductor turn insulation is made of high temperature resistant insulation paper, and the low temperature area is made of insulation material with low temperature coefficient.

Performance characteristics:

1.Low loss:

The iron core is made of high quality and high penetration cold rolled silicon steel sheet. Swiss iron core automatic stacker adopts vertical and horizontal shearing, multi-level full tilting and automatic stacking. Iron core binding adopts integral pressing and PET tape binding technology, which effectively reduces the no-load loss and no-load current of the transformer. The performance index of the transformer is superior to the national standard.

2. Low noise:

The electromagnetic noise of the iron core mainly causes the noise of the oil-immersed self-cooled transformer. In order to reduce noise, our company has taken the following measures:

1) Low flux density design

2) High-quality high permeability silicon steel sheet

3) Swiss automatic palletizer is used to control the palletizing accuracy.

4) Reliable clamping measures

5) Special damping measures

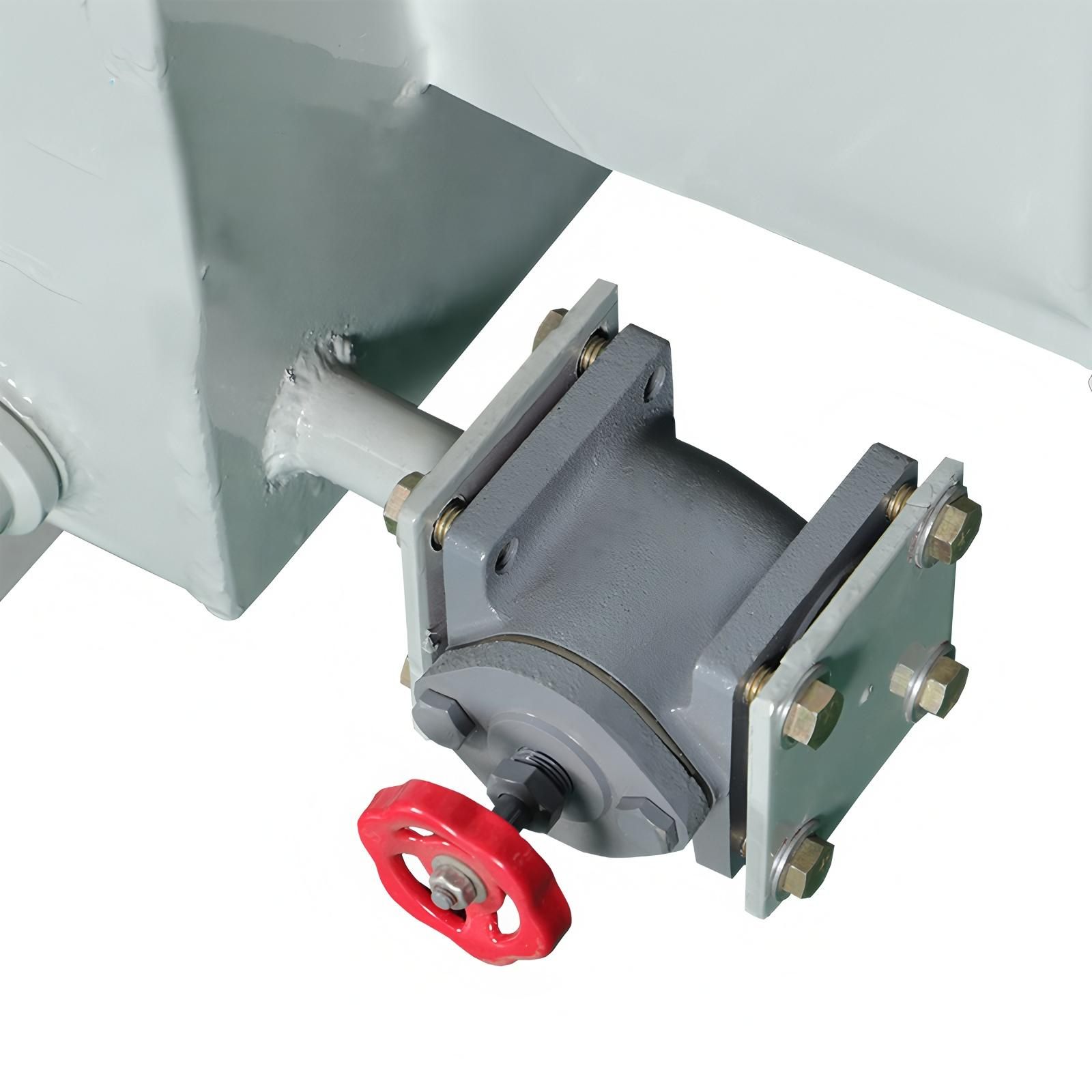

3.No leakage:

The oil tank and oil reservoir are tested for positive and negative pressure leakage to ensure that there is no oil leakage during normal operation. Flange groove structure is adopted for component installation, and all sealing elements are made of high-quality disposable acrylic rubber to prevent oil leakage.

4. Strong short circuit resistance:

In order to ensure that the transformer can withstand the impact of short-circuit current without causing any thermal or mechanical damage, our company has taken the following measures in the design and manufacturing process:

1) Reasonable ampere turn balance calculation of transformer coil using semi-hard copper wire

2) Calculation of the strength and stiffness of the core clamping components to meet the safety requirements of the maximum short-circuit mechanical force

3) Compact the high-density cardboard winding gasket

4) Winding is assembled and compressed as a whole to ensure assembly accuracy and short-circuit resistance.

5) Special damping measures

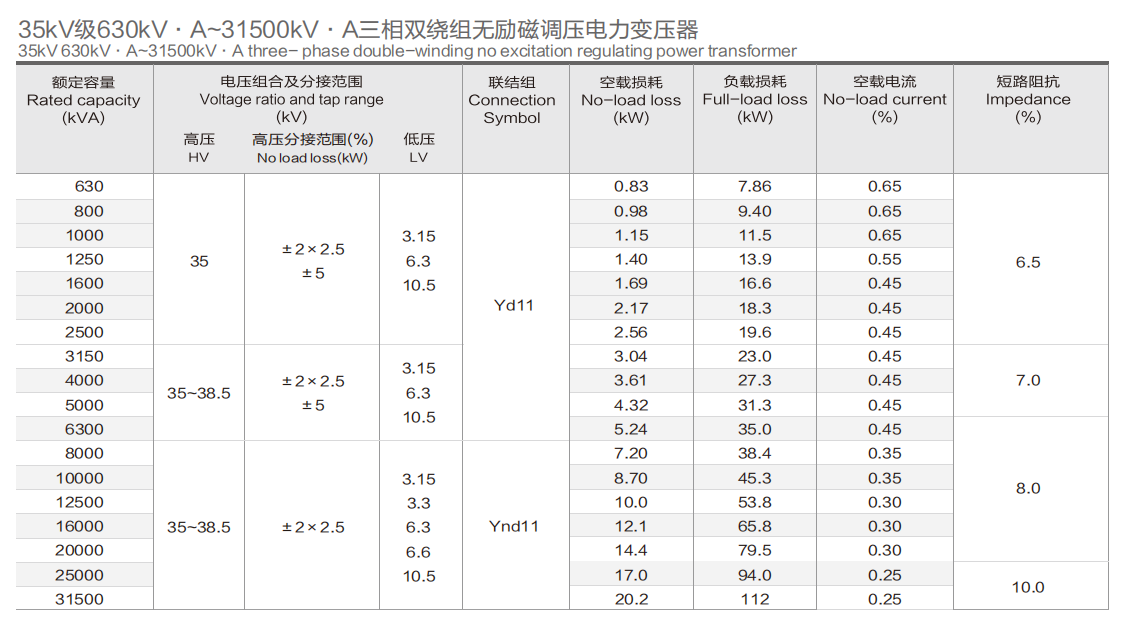

Data parameters:

Product Details:

연락처를 남겨주시면 영업 시간에 연락드리겠습니다

홈 >

홈 >